A Comprehensive Enterprise Integrating Scientific Research, Production And Sales

PRODUCTS

CONTACT

E-mail:

lh@sfvalves.cn / sc@sfvalves.cn

Phone/WhatsApp:

Address:

No. 4 Road, Industrial Development Zone, Botou City, Hebei Province, China

Republic of Vanuatu H44X-Rubber flap check valve

Category:

Republic of VanuatuCheck Valve Series

Product Description

Introduction to HC44X Rubber Plate Check Valve

The HC44X check valve, also known as a check valve, is designed to prevent the medium in the pipeline from flowing back. The valve that relies on the flow and force of the medium to open or close itself, in order to prevent the backflow of the medium, is called a check valve. Check valves belong to the automatic valve category and are mainly used in pipelines with unidirectional flow of medium. They only allow medium to flow in one direction to prevent accidents.

Performance characteristics of HC44X check valve

The HC44X rubber plate check valve is composed of a valve body, a valve cover, a valve disc, and a spring. It is mainly used at the outlet of pipelines in industrial sectors such as water supply and drainage systems, petroleum, and chemical industries to prevent medium backflow. Due to the inclined design of the sealing ring of this product, the closing time is short, which can reduce water hammer pressure. The valve disc is made of rubber and steel plate through high-temperature compression, which is resistant to erosion and has good sealing performance. The product structure is simple, and maintenance, repair, and transportation are all very convenient.

Three component materials

| Part Name | Materials |

| Valve body and valve cover | Nodular cast iron |

| Valve flap | Nodular cast iron+EPDM |

| Filler | EPDM |

| Hexagonal socket nut | Stainless steel |

| Shim | EPDM |

Main technical parameters

◆ Nominal pressure: 1.0-1.6 MPa

◆ Nominal diameter: 50-400mm

◆ Working temperature: 0-80 ℃

◆ flange standard: EN1092-2/DIN3202 F6

◆ Test standards: EN1074-1 and 2/EN12266

◆ Applicable medium: clean water

◆ Drive mode: automatic

◆ Compliant with standard: DIN3202 F6/EN1074-3

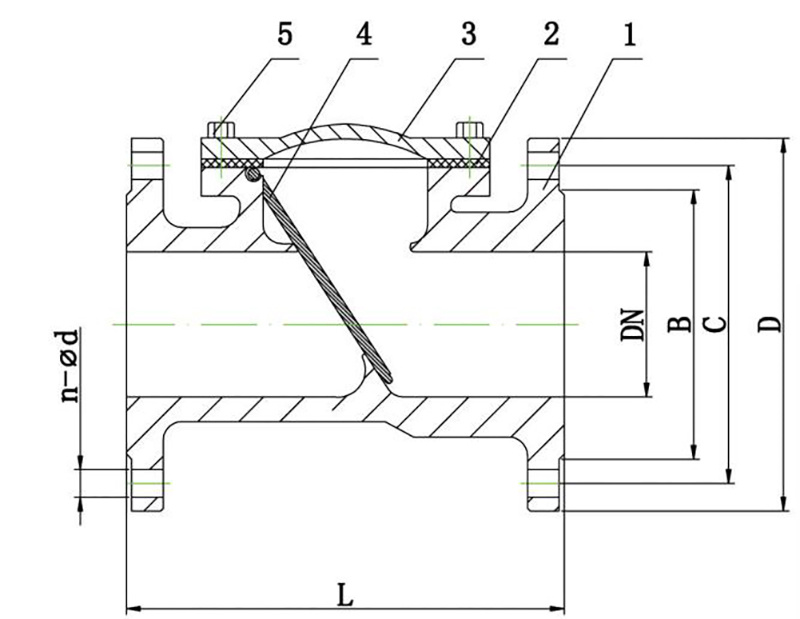

Structural diagram

| Size | L | D | C | B | n-d | b | f | ||

| DN50 | 200 | 165 | 125 | 99 | 4-19 | 20 | 3 | ||

| DN65 | 240 | 185 | 145 | 118 | 4-19 | 20 | 3 | ||

| DN80 | 260 | 200 | 160 | 133 | 4-19 | 8-19 | 22 | 3 | |

| DN100 | 300 | 220 | 180 | 154 | 8-19 | 22 | 3 | ||

| DN125 | 350 | 250 | 210 | 184 | 8-19 | 24 | 3 | ||

| DN150 | 400 | 285 | 240 | 210 | 8-23 | 24 | 3 | ||

| DN200 | 500 | 340 | 295 | 265 | 8-23 | 12-23 | 26 | 3 | |

| DN250 | 600 | 405 | 350 | 355 | 319 | 12-23 | 12-28 | 27 | 3 |

| DN300 | 700 | 460 | 400 | 410 | 370 | 12-23 | 12-28 | 28 | 4 |