A Comprehensive Enterprise Integrating Scientific Research, Production And Sales

PRODUCTS

CONTACT

E-mail:

lh@sfvalves.cn / sc@sfvalves.cn

Phone/WhatsApp:

Address:

No. 4 Road, Industrial Development Zone, Botou City, Hebei Province, China

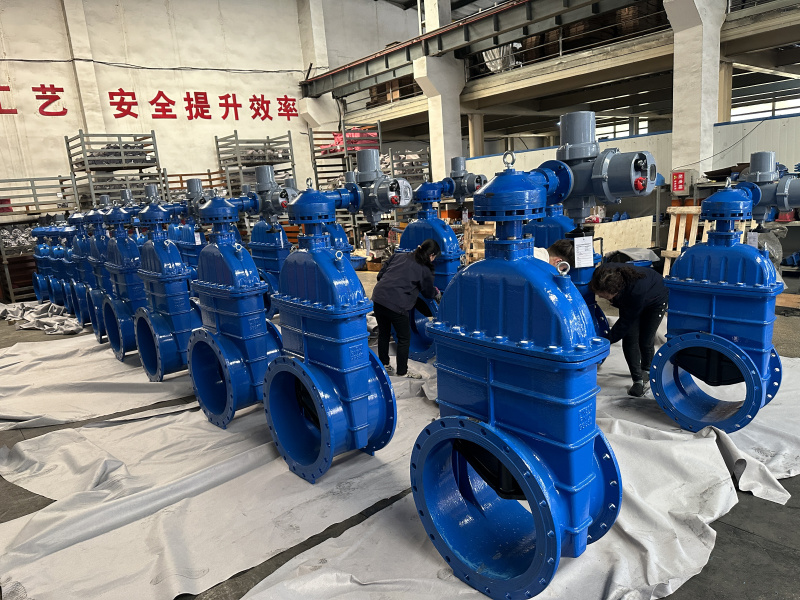

El-Salvador Electric soft seal gate valve

Category:

El-SalvadorGate Valve BS5163

Product Description

|

|

Introduction to Gate Valve Products

Various electric actuators can be installed according to user requirements to achieve remote control and automatic control. In addition to the advantages of elastic seat sealed gate valves, it also has the characteristics of sensitivity, reliability, and easy installation.

Usage characteristics of Z945x gate valve

1. Z945X Soft Seal Gate Valve Integral Sealing: The valve adopts integral sealing, which has good covering performance and precise geometric dimensions, ensuring reliable sealing and long service life.

2. The Z945X soft sealed electric gate valve is lightweight: the valve body is made of ductile iron, which is lightweight and easy to install.

3. Z945X Soft Seal Electric Gate Valve Flat Bottom Seat: The bottom adopts the same flat bottom seat design as the water pipe, which does not produce debris accumulation and provides a more reliable seal.

4. Z945X soft sealed electric gate valve is corrosion-resistant: the inner chamber is coated with non-toxic epoxy resin to prevent corrosion and rust. It can not only be used for drinking, but also for sewage systems.

5. Z945X Soft Seal Electric Gate Valve with Three "O" Seals: The valve stem adopts three O-ring seals, with low friction resistance, lightweight opening and closing, and no water leakage.

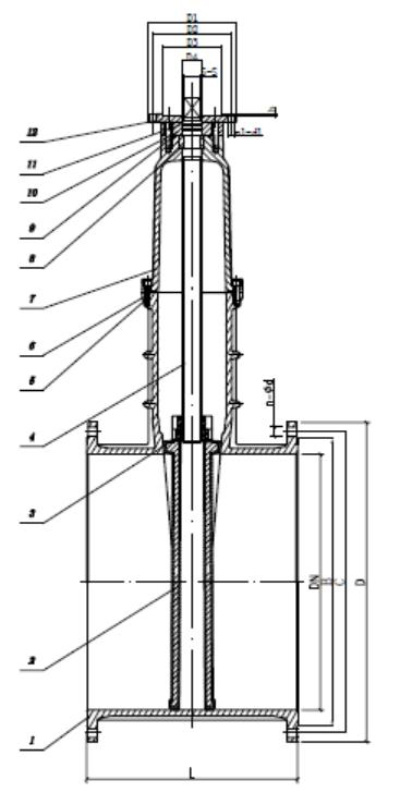

Part material

| Part Name | Material |

| Valve body and valve cover | Nodular cast iron |

| Ram | Nodular cast iron+EPDM |

| Valve stem | Stainless steel |

| Stem nut | Cast brass |

| Filler | EPDM |

| Hexagonal socket nut | Carbon steel |

| Shim | EPDM |

Main technical parameters

◆ Nominal pressure: 1.0-1.6 MPa

◆ Nominal diameter: 500-1200mm

◆ Working temperature: 0-80 ℃

◆ Flange standard: GB/T 12233-2006

◆ Test standard: GB13927 AP1598

◆ Applicable media: water, oil, gas, and corrosive media

◆ Driving method: Electric

◆ Compliant with standard: GB/T 12233

|

||||||||||

| Size | L | D | C | B | n-d | b | ||||

| DN500 | 457 | 670 | 715 | 620 | 650 | 582 | 20-28 | 20-32 | 26.5 | 31.5 |

| DN600 | 508 | 780 | 840 | 725 | 770 | 682 | 20-31 | 20-37 | 30 | 36 |

| DN700 | 610 | 895 | 910 | 840 | 840 | 794 | 24-31 | 24-37 | 32.5 | 39.5 |

| DN800 | 660 | 1015 | 1025 | 950 | 950 | 901 | 24-34 | 24-40 | 35 | 43 |

| DN900 | 711 | 1115 | 1125 | 1050 | 1050 | 1001 | 28-34 | 28-40 | 37.5 | 46.5 |

| DN1000 | 811 | 1230 | 1255 | 1160 | 1170 | 1112 | 28-37 | 28-43 | 40 | 50 |

| DN1200 | 1015 | 1455 | 1485 | 1380 | 1390 | 1328 | 32-40 | 32-49 | 45 | 57 |